Folding Arduino PET Walker

Overview:

During my first co-op as a systems test engineering co-op at iRobot, I had access to industrial 3D printers such as Objet, Fortus, MarkForged, and HP platforms and I had to take advantage of the resources in the limited time. Being very interested in soft robotics, and having produced actuators by silicone molding, I explored the feasibility of printing an soft robotic actuator with an Objet printer with variable stiffness material printing.

Purpose:

- To experiment with the feasibility of manufacturing a soft robotic

- component with a Objet 3D printer

- Exercise practical CAD modeling skills

- Go through general procedures when designing with industrial 3D printers

Challenges:

- Printer tolerances required some iteration and testing for better understanding

- Interface between solid and flexible material needed to be substantial in area for secure adhesion

- Air pocket number, depth, and height had to be experimentally optimized

- Elastic modulus of the flexible material had to be experimentally optimized

Outcome:

- Small samples with different elastic moduli were printed to verify their strength and flexibility

- Finger modules were printed individually to verify the tolerances of the printers and the effectiveness of the fingers

- Contact surface area and configuration was altered to create resistant and durable seals between the two materials and parts

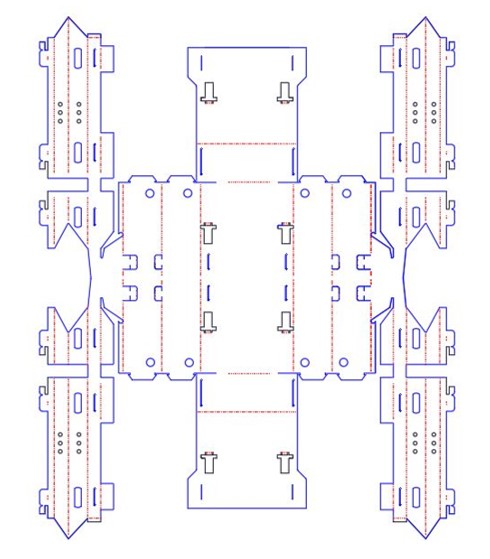

- Parts of the gripper were printed in a modular form for individual testing, and the number of air pockets, their depth, and height were verified and changed accordingly (palm, fingers, etc.)

Skills Learned:

- Developed skills to work with industrial 3D printers (Objet variable stiffness printer): Printing assemblies, tolerances, and durability expectation

- Applied PneuNets (essential design concept in soft robotics) in a gripper design